Abrasives Lesson 3: Splices

Lesson 3

Splices

Belt Splices

Great demands are placed on coated abrasive belts for a wide range of applications from heavy stock removal to surface finishing and polishing. This could not be possible if belt splice technology had not kept pace with these demands.

The belt splice must be at least as strong as the coated abrasive product itself, run smoothly, and be durable enough to outlast the life of the abrasive belt. To meet product and application demands, Carborundum Abrasives offers several different splices which fall into two basic splice types: lap and butt.

Lap Splices

The lap splice is formed by overlapping the two ends of the abrasive belt about 3/8" and then bonding with special adhesives. The abrasive grain is removed from the bottom lap with a diamond wheel (skived) prior to joining. There are two types of lap splices available: top skived or no top skived.

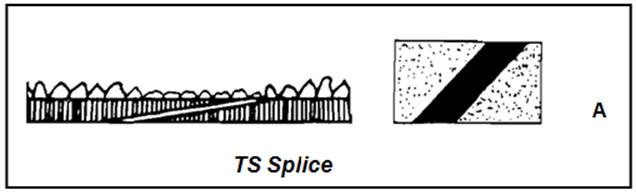

Top Skived (TS)

The top lap of the splice has some or all of the abrasive grain removed, depending upon the grit and application The TS splice is no thicker than the rest of the belt; it is smooth running, ideal for platen or hard density contact wheel support where splice marking problems are usually encountered.

No Top Skive (NTS)

No grain is removed from the top lap of the splice. Has the best splice wear resistance. Generally used on unsupported (slack of belt) or contact wheels with average resiliency that will offset any splice bump as a result of the thickness of the splice.

Butt Splices

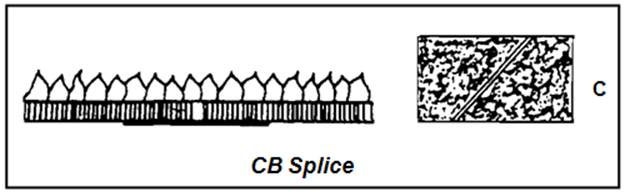

The butt splice is formed by butting the two ends of the abrasive material together without overlapping. A thin, strong, reinforced plastic film is then pressed to the backside of the splice to hold it together, creating a non-directional splice. Carborundum Abrasives offers two types of butt splices: CB and KB

CB

Our most common butt splice. A high strength splice that can be used on all grits for most applications.

KB

A special splice designed specifically for woodworking drawer sanding operations, incorporating a graphite lubricant on the backside of the splice area. This coating over the spliced film aids in reducing heat and friction buildup associated with this application.

| Competitive Splice Designations | ||

| Carborundum Abrasives | 3M | Norton |

| TS NTS CB KB |

TS NTS Fabri-Lok Fabri-Lok |

TS NTS Plyweld Plyweld |

| Recommended Lap-Type or Butt Splices for Both Cloth & Paper Products by Application | |||

| Metalworking | Backing | Recommended Splices | |

| Backstands | Cloth | NTS or CB - All grits & sizes | |

| Centerless & Wire Grinding | Cloth | CB - All grits and sizes | |

| Crankshaft Polishing | Paper or Cloth |

NTS or CB - 50 & Coarser TS or CB - 60 & Finer |

|

| Jet Blades - | Mechanized | Cloth | TS or CB - All grits & sizes |

| Offhand | Cloth | NTS - 60 & Coarser NTS or CB - 80 & Finer |

|

| Platen | Cloth | TS or CB - All grits & sizes | |

| Roll Grindinq | Cloth | CB - All grits | |

| Slack of Belt | Cloth | NTS or CB - All grits & sizes | |

| Thru-feed - Narrow Belts | Cloth | NTS or CB - 80 & Coarser TS or CB - 100 & Finer |

|

| Paper | NTS - All grits & sizes | ||

| Sectional Belts | Cloth | NTS - 60 & Coarser TS - 80 & Finer |

|

| Paper | NTS - All grits & sizes | ||

Woodworking |

Backing |

Recommended Splice |

|||

| Bull Nose or Dead Head Sander | Cloth | TS - All grits & sizes | |||

| Drawer Sanders | Cloth | KB - All grits & sizes | |||

| Edge Sanders | Cloth | TS - All grits & sizes | |||

| Mould Sanders | Cloth | TS - All grits & sizes | |||

| Stroke Sanders (Lever and Thru-Feed |

Cloth | NTS - 50 & Coarser TS - 60 & Finer |

|||

| Paper | NTS - All grits & sizes | ||||

| Wide | Single Splice Under 53” |

Cloth | TS - All qrits | ||

| Belts | Paper | NTS - All qrits & sizes | |||

| Plywood/Particle-board | Single Splice 53" & Over | Cloth | TS - All grits | ||

| Sectional Belts Pacer | NTS - All qrits & sizes | ||||

| Abrasive Planing (24, 36, 40 Grit) | Cloth | CB - All grits | |||

| Thru-Feed Sanders | Cloth | NTS or CB - 80 & Coarser TS or CB - 100 & Finer | |||

| Paper | NTS - All grits & sizes | ||||

____________________________________________________________________________________________

Questions on Lesson 3

a. TS

b. KB

c. CB

2. A splice with all or part of the abrasive grain removed from the top lap of the splice is:

a. NTS

b. CB

c. TS

d. KB

3. The lap splice is non-directional:

a. True

b. False

Courtesy of Carborundum Abrasives