Abrasives Lesson 15: Storage and Handling of Coated Abrasive Products

Lesson 15

Storage and Handling of Coated Abrasive Products

Introduction

Storage conditions are among the most important factors affecting the performance of coated abrasives. Unfortunately, it is generally ignored. Coated abrasives will usually perform at maximum efficiency only when they are properly handled and stored.

Coated abrasive products require special care in storage. The backings and some of the adhesives used in their manufacture are sensitive to climatic changes and will pick up or lose moisture according to the relative humidity of their surroundings.

Generally speaking, the grinding and finishing efficiency of coated abrasives increases as the moisture content decreases. However, when a coated abrasive product is allowed to dry out too much, brittleness, curling, and difficulties in handling may nullify the advantages of increased cut. At between 40% and 50% relative humidity, coated abrasives offer the ideal combination of cutting efficiency and ease of handling.

Effects of Poor Storage

Poor storage conditions may affect coated abrasives in one or more ways'

Excessive Humidity – may cause a softening of the bond in the case of glue bond, or resin over glue products as well as a softening of the filling material used in cloth finishing. This causes the abrasive grains to tend to push into the backing rather -than penetrate the workpiece. Frictional heat builds up tending to further soften the bond. The coated abrasive will then quickly loads and start burning the work. The effect of prolonged exposure to conditions of high humidity can result in a drop in the performance of coated abrasives amounting to as much as 50% of the normal useful life.

Excessive Dryness - results in a loss in flexibility which creates difficulties in handling. Narrow belts tend to curl or "snake" up, slowing down belt changes, Narrow belts also tend to cup (curl toward the backing) due to the shrinking of the backing as it dries out.

Paper products, particularly those coated on "A" weight paper, lose the "hand" (pliability) and become brittle as a result of prolonged exposure to excessively dry storage conditions. Waterproof paper is similarly affected.

Cloth-backed belts and discs - if the moisture content in the backing of discs becomes too high, they will reverse curl (cup toward the grain side) and become temporarily unfit for use. Both glue bond and resin bond belts will reverse the cup in the same manner - the result of excessive moisture. Excessive dryness causes cupping in the opposite direction.

Storage Facilities

Coated abrasives deliver their best performance when stored and used at recommended temperature ranges and relative humidities. They achieve their maximum efficiency at a temperature range from 60° to 80°F and at a relative humidity of 40% to 50%. The optimum conditions for the storage of all coated abrasive products are:

1. A constant temperature of 70°F (plus or minus 5°).

2. A controlled humidity of 45% (plus or minus 5%).

3. If conditions 1 and 2 are impossible to obtain, make sure that all coated abrasives are kept off concrete floors, and away from other sources of dampness, as well as away from hot air ducts or heaters.

Of the two storage conditions, temperature and humidity, the latter is by far the most important.

Storage Room

When possible, coated abrasives should be stored in a room with inside partitions, rather than outside walls of a building. The ideal storage room should have no radiators or hot air inlets. If heat must be supplied to the room, the coated abrasives should not be close to the source of the heat.

For customers stocking relatively large quantities of coated abrasives, a humidity-controlled storage room is recommended. Such a storage room will soon pay for itself by providing a uniformly higher quality product with resulting in increased productivity and can be inexpensively built and equipped for the recommended conditions.

Handling

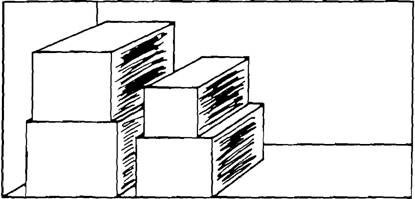

Besides the atmospheric conditions which must be considered, easy and quick product identification is important. Plenty of good shelving will aid in storage, handling, inventory, and ease of location.

- Coated abrasives should be kept in closed cartons until the product is actually used.

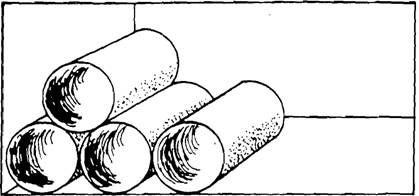

- Bulk rolls should be laid flat rather than stored upright on the ends.

- Cartons, boxes, and wrapped rolls should be kept intact until the coated abrasive is needed.

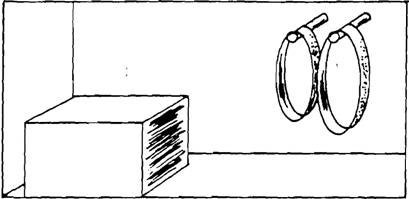

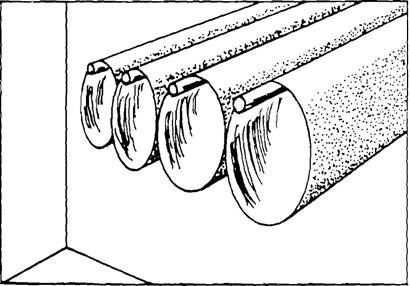

- Belts should be hung on fixtures of adequate diameter, not on nails or small rods, This is particularly true for wide belts. Wide belt boxes should not stand on end. Giving an entire carton of belts to an operator is usually poor practice; the extra belts are easily subject to damage because of inadequate storage facilities in the machine area.

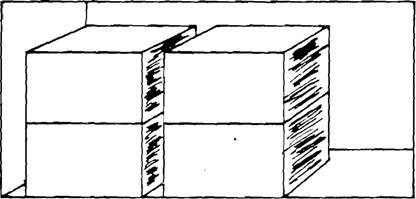

Proper Storage of Coated Abrasives

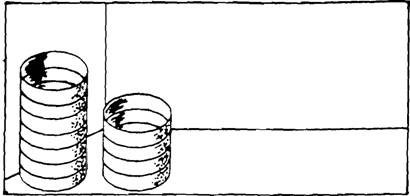

Wide rools on curved side

Narrow rolls stacked

Belts kept in boxes (Also fibre-backed Discs, Nolap Bands,

etc., kept in boxes)

Belts - both in boxes and hung loosely on pegs

Carton stock kept in original packages

Sheet stock stacked in ream packages

Proper Storage of Wide Belts

____________________________________________________________________________________________

Questions on Lesson 15

1. When the relative humidity is low, the grinding efficiency of coated abrasives:

a. increases

b. decreases

c. remains the same

2. If stored near heat ducts or in rooms near furnaces or ovens, the high-temperature causes coated abrasives to become:

a. brittle

b. soft

c. midewed

3. Coated abrasives that are stored under conditions of excessive humidity will tend to:

a. cut faster

b. quickly load

c. be difficult to handle

4. The best way to store coated abrasives is:

a. belts should be hung on nails

b. kept in closed cartons until used

c. remove from cartons and place on shelves

5. Coated abrasives operating at can be expected to give a good performance

a. 85% relative humidity

b. 95°F

c. 40% relative humidity

Courtesy Carborundum Abrasives